By Jeff Carter, DDS

Three facility scenarios require doctors to strategize and generate purchase lists for new dental equipment. These three scenarios include:

- Remodeling/addition and refurbishing of an existing facility

- Newly constructed facility with a blend of equipment purchased new and transferring existing equipment from the current facility

- Startup facility with all equipment purchased new

Typically, doctors resource a dental equipment dealer’s equipment specialist to generate an initial list for a new project.

To better understand the relationship between dental equipment manufacturers, resellers/dealers, and you, the end-user, please refer to the companion piece in the September issue of Dental Economics® titled, “Don’t Shop ’Til You Drop.” Understanding these relationships will help you make wise purchase decisions, and allay some of your concerns about “getting a good deal” when purchasing major pieces of dental equipment.

My recommendation is to generate your own list prior to meeting with dental equipment dealer representatives such as Patterson, Sullivan-Schein, or the independents in your area. The dental equipment list to which I refer pertains to the larger pieces of equipment in regard to investment and/or sizing. Dental patient chairs, delivery units, air compressors, and X-ray units are a few examples of major pieces of dental equipment. We are not referring to smaller items such as handpieces, hand instruments, materials, and consumable supplies in your self-generated list. Once you have completed an initial equipment list, I recommend you submit it to at least two dental dealers in your area for pricing.

Animosity often ensues when reps create purchase lists without your initial guidance. I have heard numerous complaints from doctors about equipment lists containing multiple items they did not want, and other items they did not know existed. It is analogous to car buying. Not many of us venture onto the new car showroom floor without a specific budget, manufacturer, model, and list of options in mind (unless we are just window shopping). While we may change our mind during the car-purchasing process, we always begin with a purchasing agenda. Dental equipment purchasing is no different.

Purchasing Scenario 1: Remodeling/addition of existing facility

This type of project is often associated with a growing practice that needs to expand clinical space (adding one or two more operatories), to replace outdated pieces of existing equipment, and to create a new look that patients will perceive as modern, up-to-date, and cutting-edge. Many of you might have purchased or acquired practices from retiring practitioners, then worked hard for several years, and are now in a position to expand and renovate the practice.

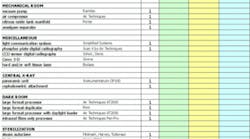

If this scenario fits your current practice, then please refer to the Major Equipment Purchasing Guide on this page as you formulate preliminary answers to the following questions and assumptions. This specific equipment purchasing guide has been formatted to assist general practitioners.

• How many new operatories will you add?

In the column titled New Purchase Operatory Equipment, write in quantities based on the number of new operatories. If you expand by two operatories, for example, you will typically need two new patient chairs, two delivery units, four stools, two periapical X-ray units, and two dental patient lights. If you choose to purchase high-quality, top-of-the-line equipment, you can expect to invest $20,000 to $25,000 per operatory to obtain these major pieces of equipment. Also, consider if you will require any of the additional units listed in the Operatory category.

• Of your existing operatories, how many will receive new equipment?

For example, if two of your three existing operatories have 20-year-old pieces of equipment, it may be time to replace equipment in those operatories. The challenge with remodeling is the difficulty of blending the old with the new without creating spaces staff and patients do not want to use. Eclecticism has a more limited successful expression in a dental facility. The cliché is you can always spot the hygiene operatory because it contains 20- year-old equipment and has no windows. Refer to the Equipment Guide and list quantities for existing operatories that will receive new major pieces of equipment, and update those totals.

• Is your dental mechanical system able to support the utilities demand created by additional operatories?

Vacuum pumps and air compressors are rated by the number of users able to access vacuum and compressed air simultaneously without significant performance loss. If your unit(s) is currently performing at a minimal acceptable level, or even poorly, assume one or both need to be replaced. For example, you can expect to invest approximately $12,000 for a new vacuum pump and air compressor in a five- to six-operatory facility.

• Will you update equipment in the lab and sterilization areas?

Equipment for each of these clinical support areas has evolved considerably in recent years. Many general practitioners have expanded beyond the typical “pour up and polish” lab to create lab spaces even prosthodontists would envy.

• Will your remodeled facility include some lab equipment updates?

Sterilization advancements include cassette systems, instrument washers, handpiece lubricators, and more efficient sterilizers. You may want to consider the Miele Thermal Disinfector as a one-stop replacement for instrument rinsing and scrubbing, ultrasonic action, rinsing, and drying. You can expect to invest approximately $6,000 on this unit. Refer to the guide as you sort through typical equipment options for lab and sterilization areas.

• Will you require large investment purchases of equipment listed in the guide’s miscellaneous category?

Many times the driving force to remodel a current office is your desire to present a cutting-edge facility to patients, including the latest in dental technology. At least two monumental investment decisions are often required in this category:

The first decision is whether or not to make a full conversion to digital radiography. If your facility currently uses large-format films, the investment decision is even more difficult. Expect to invest approximately $50,000 or more for three CCD intraoral sensors and a panoramic CCD sensor. This is an investment in sensors only, and does not include X-ray units, software, computer hardware, monitors, network cabling, etc. Much of the popularity of Scan-X and reusable phosphor plates is from the comparison investment of approximately $20,000 for the scanner unit and phosphor plates (including large format) vs. the CCD sensors, which cost $50,000 or more. Obviously, the CCD sensor’s image capture is nearly instantaneous and a different technology from the phosphor plate scanning process. If you have not yet answered the CCD vs. phosphor plate question, you will need to at some point in your career.

A second large-investment decision is whether or not you will incorporate a CEREC3 unit into your facility. One of my current design clients reports that her practice’s monthly lab bill decreased to 2 to 4 percent of her monthly production from 8 to 10 percent with the addition of the CEREC3. The Patterson financing option readded 2 percent to the monthly total for a net reduction in overall lab costs against production of approximately 5 percent. Expect to invest approximately $100,000 for a CEREC3.

Purchasing Scenario 2: Newly constructed facility

Creating an itemized equipment list for a newly constructed facility that will utilize some transferred existing equipment is an expanded version of what we discussed in Scenario 1. In this scenario, it is typical to see facility increases of at least two or more operatories when designing a new office. It is also not uncommon for doctors to increase their facility functional capacity by four or more operatories with the intent of bringing in associates or partners. Items to consider in this scenario include:

- How many operatories with existing equipment can be transferred from the existing facility?

- Of the new facility operatories, how many will you equip initially? Do the math, refer to the Equipment Guide, and quantify how many operatories of new equipment will be required.

- Assume you will need a new vacuum and compressor when increasing facility size by two or more operatories.

- Assume you will need at least one new sterilizer when increasing facility size by two or more operatories.

- Assume you will purchase at least two or three pieces of lab equipment as you advance beyond the typical lathe, model trimmer, and vibrator configuration.

- Assume your new facility will not have a dark room. If you are not making the conversion to digital radiography, plan a conversion strategy. One strategy is a developer with a daylight loader attachment placed in a temporary location that can later be converted to useful space. In this strategy, you should design and install all the necessary cabling and technology infrastructure that supports a future conversion to digital radiography.

- Assume that large-investment equipment purchases in the guide’s miscellaneous category, other than digital radiography conversions, will not occur in this scenario at this time. Because of the associated investments required in a new facility, it is probably not the time to take on the added debt of a CEREC3, and a new hard-tissue laser.

When equipping a newly constructed facility, there is often a misconception that all equipment is a new purchase. This is rarely the case, and not recommended. Existing equipment can often be reupholstered and even electrostatically painted to match a new facility design palette. Make use of all existing equipment that is performing successfully in your current facility.

Refer to the equipment guide and fill in quantities, making choices in each of the categories.

null

Purchasing Scenario 3: Startup facility with all equipment purchased new

This is a difficult scenario for practitioners.

For the recent graduate who is determined to start a new practice, the financing challenge of equipping a new facility from scratch is daunting. The existing equipment list often consists of two handpieces, an explorer, and a half-empty container of sandpaper disks remaining from dental school.

For established practitioners who have sold or transferred an existing practice and equipment to another doctor, a new facility also requires that all major equipment be purchased new. Ideally, the sale of an existing facility can help offset a portion of the equipment investment required in a new facility. If no additional equipment proceeds are available, purchasing new equipment for a new facility skews the project investment categories. This can result in reduced funds being available for design objectives you may have.

If you are an experienced practitioner and your project falls into this scenario, refer to the guide and assume you will require basic major equipment in all categories.

If you are a recent graduate, the following information should help you better understand what is generally possible for a startup practice facility:

- Assume that the typical loan maximum a new graduate can secure on equipment is approximately $340,000. This assumes no outside funding or assets available from parents, spouses, or others.

- Assume you will fully equip two operatories to start.

- The fully equipped operatories will require a dental patient chair, periapical X-ray unit, delivery unit(s), doctor’s stool, assistant’s stool, and dental patient light. If you purchase the highest-quality equipment available, each operatory will require an investment of $20,000 to $25,000 for these major pieces.

- There are two viable options to consider for cabinetry systems:

Dental cabinetry systems can be purchased for a facility from your equipment dealer, and are often manufactured by the same company as a delivery unit and/or dental patient chair. Most systems offer different configurations to meet a practice’s preferences.

You may also choose to have an independent, dental specialty company custom-design your office and cabinetry systems. In custom-designed facilities, cabinetry systems are built in a millwork shop as part of an office’s total construction. These millwork-fabricated systems are considered “dental equipment” by most specialty lenders, and are assumed a part of equipment purchased similar to dealer-purchased cabinetry.

- In addition to the operatory equipment, you will need - at a minimum - a vacuum pump, air compressor, steam autoclave, ultrasonic unit, lathe, vibrator, and model trimmer.

- For processing radiographic images in a startup, it is difficult to budget for digital radiography initially because of the other costs associated with a new practice. The investment required for the integrated technology system that supports the digital radiography sensors or scanning unit is considerable. Assume you will not have the funds to include a panoramic X-ray unit in your initial purchases of equipment.

Three radiology options that may fit a recent graduate’s startup facility budget would include:

- Purchase X-ray film and utilize an auto-processor with daylight loader such as an Air Techniques Peri-Pro. Initially, you do not need the larger-format film processors such as an Air Techniques AT2000. However, when you can afford a panoramic X-ray unit, you can convert to digital radiography.

- Purchase the Scan-X option that does not include scanning of large- format films. The “intraoral images only” version of Scan-X is not as costly, and still affords the capability to acquire digital intraoral images of all sizes.

- Purchase one CCD sensor and share that sensor for all intraoral images. The sensor sizing and image quality of Dexis make it a good choice in this situation.

I hope this information and accompanying guide are useful as you ...

start makin’ a list,

submittin’ it at least twice,

tryin’ to find out who’s got a great price ...

Dr. Jeff Carter is co-owner of the Practice Design Group, based in Austin, Texas. PDG specializes in providing architectural, interior design and equipment, and technology integration services to dentists nationwide. Dr. Carter may be contacted by phone at (512) 295-2224, by e-mail at [email protected], or by visiting PDG’s Web site at www.practicedesigngroup.com.