By Jeffery C. Hoos, DMD, FAGD

Success in private practice is can be achieved when the doctor and staff find the correct balance between three important factors: art, science, and business. Delivering beautiful dentistry gives the doctor great satisfaction and makes patients most appreciative of the services they have received — this is the art of dentistry. Producing sound and esthetically pleasing restorations based upon applied scientific principles and by using the latest materials fulfills the science of dentistry. Providing your services in a friendly, timely manner and at an accepted fee is the most important part of the business of dentistry.

There are often scientific and business aspects of dentistry that must also be considered besides the delivery of your services. This is the support function of your staff and facility, providing a clean and sterile environment within which the doctor and staff must operate. This article is intended to give an overview of an often overlooked, or I should say misunderstood, component of providing a clean and sterile environment — hard-surface disinfectants.

null

Hard-surface disinfectants are used by hundreds of thousands of healthcare professionals to kill bacteria, viruses, and fungi on various surfaces found within their offices and operatories. While these products are absolutely necessary, it is important to remember that not all are created equal, nor are all as effective as you might be led to believe in every circumstance. Some have been found to be highly toxic, even potentially carcinogenic to the office staff, while others are much safer and equally, if not more, effective. Some may not actually kill the target or "benchmark" organism, (e.g.: TB) that you would have expected it to, or not kill it quickly enough to be practical for your particular application.

A brief discussion of the existing types of hard-surface disinfectants available on the market today and what you should look for in choosing the perfect product for you and your office follows.

First, every EPA-registered hard-surface disinfectant product's label must include an ingredient statement that lists the concentration of each active ingredient found in the product. All disinfectants must also clearly list an EPA registration number on the products label and list the kill times for the microorganisms that the product claims to kill. For EPA registration purposes, every antimicrobial product must satisfy specific regulatory requirements, including those pertaining to safety and efficacy, which are proven through exhaustive independent testing. Minimum efficacy test requirements for sanitizers, disinfectants, and sterilants differ greatly from one to another so it is important to note whether the product is called a sanitizer, a disinfectant, or a sterilant. Disinfectants comprise the largest number of antimicrobial products found on the market today and come in many different chemical compositions and delivery systems, which only further confuses the issue of which product to use in your office.

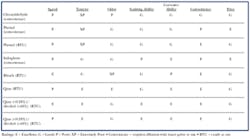

Generally speaking, these disinfectants can be placed into seven categories based on the specific active ingredient (the chemical or combination of chemicals in the product that actually kill the target microorganisms) they contain. They are glutaraldehyde-based, phenol-based, iodine-based, sodium hypochlorite (bleach)-based, sodium bromide/sodium dichloroisocyanurate dihydrate-based, quaternary ammonium chloride-based, and quaternary ammonium chloride/alcohol-based products. All of these have varying degrees of efficacy and speed of kill, and may also carry drawbacks ranging from (minor) the need to mix or a mild odor to (major) staining, extreme toxicity, or loss of efficacy under imperfect conditions. The next six paragraphs further explain each category's pros and cons.

- Glutaraldehyde-based products are generally cheap and are not known to stain or corrode surfaces that they are applied to. Where the disadvantages lie is in their need to be mixed, the foul odor they produce, their toxicity, and their need for contact times up to 20 minutes. These products are more specifically meant to be used as cold sterilants, not as hard-surface disinfectants.

- Phenol-based products generally don't have much of an odor and do not stain or corrode the surfaces that they are applied to, and have the increased benefit of low price when concentrated formulas are purchased. Where these products lose points is in the fact that they are not very fast-acting (typically 10 minutes), a residue will eventually build-up on the surfaces in your operatory, and they are found to be extremely toxic, often causing sinus and respiratory problems, as well as headaches and nausea due to overexposure and lack of proper ventilation. Visit the EPA's Web site at (www.epa.gov/ttn/atw/hlthef/ phenol.html) for more information regarding the toxicity of phenol-based products.

- Iodophore-based products are generally low odor, non-corrosive, and extremely cheap, but they lack speed of kill and the dilution and contact times are far too critical for their efficacy to be consistent and practical in most healthcare settings.

- Bleach-based products are well-known for their killing power, speed, and safety, but they tend to be extremely corrosive and damaging to surfaces and usually contain a heavy odor. They are not typically recommended for use on most surfaces found in a dental operatory.

- Quat-based products are the most commonly used type of hard-surface disinfect for both the healthcare and consumer industries and, aside from the speed of kill (also typically 10 minutes), they have been found to be very effective and safe. One drawback is the potential for staining and residue to be left behind, depending on the amount of quat found in the particular products formulation. The higher the level of quat, the more it will lead to staining.

- Quat/Alcohol-based products appear to be the safest and fastest products on the market today. They also kill a wide range of pathogens and don't typically contain any staining or corrosive characteristics. They are fairly cheap, especially for a ready-to-use product, and don't appear to present any health hazards. They do tend to contain an odor, although it usually dissipates rather quickly. The higher the level of alcohol found within the particular product, the faster the kill rates will be. Another benefit of these products is that they can be found in both the traditional ready-to-use liquid and convenient presaturated towelette delivery forms.

Click here to view the What Products are What list.

Clearly, with the excess of disinfecting products from which to choose, selecting the one that meets your specific needs is crucial and extremely difficult. Ease of use (convenience), kill times (speed), esthetics (odor, residue, appearance, staining), effectiveness as determined by substantiated label claims, compatibility, cost, and toxicity are the factors which ultimately will be weighed when making your decision. As you may notice from the chart on the article's first page, there are not many product categories that score good or better in every column. As a matter of fact, there is only one.

The CaviCide family from Metrex is one of the new generation quat/alcohol technology products available today.

null

It is important, in fact critical, that the product chosen works as claimed, to protect both the user and patient against potentially harmful, transmittable diseases, but also that it does not cause more harm than good to the user and the surrounding personnel due to toxicity. With increasing pressure on the dental staff to attend to more patients in less time, it is also imperative that the treated surfaces are germ-free when the next patient arrives. A 10-minute kill time does little good if the next patient is being seated within five minutes of your disinfection routine.

In conclusion, look at the required ingredient statement on the product's label to determine its contents, and also look at the kill times and the pathogens it claims to kill. Make sure that the product kills a wide range of these pathogens and especially the pathogen ("benchmark organism") that you might be most concerned with in your office. Do not use a product that is not EPA-registered, no matter what claims it makes on its label. Also, know the drawbacks of the type of chemistry that you are using. They may kill a broad spectrum of pathogens, but they might also be harmful to you, your patients, and the expensive equipment found in your office.

By using the right applied science (choosing the correct chemistry for you and your staff), hard-surface disinfection can be done in a safer, better, and more efficient manner. Doing this can only better your current practice. It's all in finding the proper balance.