By Joe Kennedy

I had the good fortune to become associated with the dental profession and industry in the late '60s and early '70s. It was a time when both were experiencing major changes, and I was privileged to contribute to those changes, which were to have a major impact on the way dentistry would be practiced and how the industry would respond to dentists' needs.

This was a time when "sit down four-handed dentistry" was being introduced. Prior to this, dentists practiced standing up with their patients seated in barber-type chairs. Dental assisting was unheard of, and dentists performed all procedures alone. While dentistry was an honored profession, dentists had to endure many hardships, mainly from health issues related to posture (they had to stand and balance most of their weight on one leg, and had to contort their head and shoulders). In those days, dentists stood out in a crowd. The right shoulder of a right-handed dentist was always noticeably higher than his or her other shoulder. Consequently, a substantial amount of dentists' income was spent on chiropractic care — if they could afford it.

Equipment used by dentists at that time was quite archaic. Handpieces (or drills as they were called at the time) were connected to electric motors by belts, and were very slow compared to the pneumatic high speed handpieces used today. A combination of the time it took to remove tooth material and the excessive heat buildup accounted for most of the pain the profession "inflicted" on its patients. The lack of modern anesthesia and methods were also major contributors to the pain.

It's hard to imagine now how those of us who experienced this pain actually endured it. The inefficiencies caused by the design of the equipment and the lack of efficient practice methods resulted in a relatively low income for dentists compared to others in the health-care profession at the time. While it's hard to believe, in the '60s and '70s a lot of dentists were reluctant to adopt modern methods of practicing dentistry. Those reluctant to change were either forced to eventually accept the changes or face challenges keeping their practices open.

Today's practice of dentistry is literally light years ahead of the way dentistry was practiced back then. The main purpose of dentistry is no longer "drill and fill" or extraction. Cosmetic dentistry has added a new dimension to the lives and profitability of modern dentists. Patients have profited greatly because of the incalculable value of a beautiful smile. People's lives have literally been changed for the better. I can personally attest to this because on many occasions, patients of my daughter, Dr. Kennedy-Townsend, have enthusiastically shared this message with me. For most, a visit to a dentist who practices modern dentistry is no longer a dreaded experience, but can be quite enjoyable — really!

Since the introduction of "sit down four-handed dentistry," dental equipment manufacturers have made many improvements on their products. For the most part, they have responded to the needs for equipment to support the practice of modern dentistry. Unfortunately, those that didn't are no longer in business. However, just as some dentists were reluctant about the changes needed to practice modern dentistry, some manufacturers are reluctant to accept the more modern and efficient methods for delivering their message to dealers and prospective customers.

I am pleased to report that many manufacturers have drastically reduced the amount of paper they distribute, using paper only for special purposes such as bids and presentation folders. However, literally thousands of tons of paper catalogs, brochures, and flyers are still being produced, with most ending up in already overburdened trash dumps. This is a tremendous waste of time, materials, and precious trees, and the cost is astronomical! The question that begs to be asked is why? Is it because they, like many, are reluctant to accept change? Could it be as basic as "the fear of loss is so much greater than the hope for (or expectation of) gain"? Or could it be that those of us who try to bring about change are not getting our message across as well as we should? I suspect it is a combination of these.

This article is an attempt to do a better job of delivering the message. The message is quite simple — current technology makes it possible to deliver a manufacturer's message as well or better in an electronic format than with archaic paper methods, and at a dramatically lower cost!

So, what do manufacturers and suppliers that haven't done so already need to do to change the way they deliver their messages?

First, they must accept a simple and proven fact — when, at a tremendous cost, they create paper literature, box it up, and send it to their dealers, they have no way of knowing whether any piece of it ever participates in the sale of their product, and most of the time it does not! Often, when some part of it does, the rest that accompanies it gets thrown away.

Second, they need to search the many different ways they can deliver their message electronically and decide which method is best for them. One of the methods is to create their own website and make their data available to download. While websites are a positive step in the right direction, they pose one major drawback — since all websites are designed differently, those wishing to download data must learn how to navigate it, and some may become frustrated when they can't. Also, most orders consist of many different products in various configurations from multiple manufacturers. This requires numerous visits to different websites and can be very time consuming.

Another method is for the manufacturers/suppliers to subscribe to a service that distributes electronic data, and ask their dealers to access their data this way. While this is far better than paper methods, one of the disadvantages is that data can be out of date. Also, creating an order requires additional software and procedures, thus adding to the time needed to create an order.

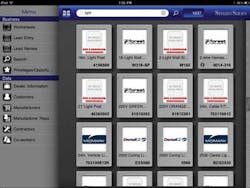

The best choice by far for delivering a message and creating a sale is a system that addresses all the needs for the sale of dental equipment. This typically includes issues of size and space (the size of the equipment and space available), template and specifications, features and benefits, interactive pricing data, and financing rates and plans. All of this is in an electronic format and can produce a sale without a single piece of paper, and in many cases can be done in a single sales call!

Another very important aspect of delivering a manufacturer/supplier's message and creating a sale is the method of delivering the electronic data. For years laptops have been used for this purpose and have worked very well. However, they present challenges during a sales call. First, where does one place the laptop so that both the salesperson and dentist can view it? Secondly, there's a time delay while the computer boots up. Tablets are rapidly replacing laptops due to their convenience. For example, a sales call can be made while the salesperson holds the tablet in one hand and creates the order with the other hand, and this can be done while walking down the hall with the dentist. Older dentists are impressed by this method, and younger dentists expect it!

Obviously, salespersons are key elements in the sales process. The methods they use can either make or break them and their companies. The more successful ones stand out in the crowd when they embrace change and implement modern sales technology. Conversely, as it was with standup dentistry and being easily spotted in a crowd, so are those salespersons who still cling to the ways of the past by travelling with their trunk full of catalogs (most of which are out of date), and making sales calls with a pen and paper. Sadly, their fate, and perhaps the fate of their company, will probably be the same as that of the dentists of the past.

It has been said that, "The only thing new is the history we never learned." I respectfully declare that history is repeating itself in our industry, and the lesson to be learned is that those accepting and implementing beneficial changes are the ones who will succeed, and those that don't will eventually fail.

Joe Kennedy is the president of DentaCAD Corporation. For more information, Kennedy can be reached at (770) 271–4142 or by e–mail at [email protected].