Real World Endo: Can metal treatment affect cyclic fatigue of rotary files?

By Kenneth Koch, DMD, and Dennis Brave, DDS

The separation of rotary instruments still remains the top concern among dentists performing rotary endodontics. There are two principal causes of separation - excessive torque and accumulated cyclic fatigue. In previous columns, we addressed how to handle the challenges offered by excessive torque and cyclic fatigue. In this article, we will investigate the benefits of metal treatment (electropolishing) and how this enhancement may play a role in the reduction of cyclic fatigue.

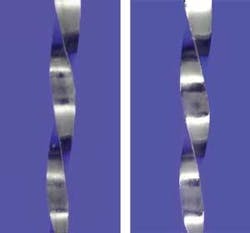

There are numerous metal treatment methods available. However, electropolishing is the treatment of choice when endodontic condsiderations are foremost. Electropolishing is a finishing technique that is used to treat nickel titanium (nitinol), stainless steel, and many other alloys. The two most common finishes for nickel titanium are electropolishing and chemical etching. Both of these methodologies remove surface material from the metal, leaving it exceedingly smooth (Fig. 1).

Advanced Materials and Technologies on its Web site (www.amtbe.com/polishing.html) describes the electropolishing process very nicely. “The process involves connecting a part to the anode of an electrolytic bath and flowing large DC currents from the anodic part (+) to a metal cathode (-) to do essentially the opposite of electroplating. Electric fields naturally focus on microscopic peaks, increasing the local material removal rate over that of valleys, resulting in a significantly smoother and more reflective surface even with minimal material removal (typically 2-3 microns).”

In addition to an improvement in surface finish, there is actually a modification in the surface chemistry of the nickel titanium. Elemental nickel is removed, leaving an oxide film of 10-20 angstroms. ATM describes these properties as ideal for surface cleanliness and very high corrosion resistance. This is particularly important in endodontics, where our instruments are continually placed into an environment of sodium hypochlorite (bleach).

Historically, metal treatment has been greatly underutilized in the manufacture of nickel titanium rotary files. Currently, there are very few companies doing metal treatment of any nature to their rotary files. Surely, most companies know the benefits of metal treatment procedures such as electropolishing. The rationale behind the metal treatment of rotary files is that such procedures extend the life and performance of a rotary file and, in fact, make it a better file (Fig. 2).

For example, electropolishing will dramatically reduce the potential for crack propagation in NiTi files. This is very significant as it has been shown, repeatedly, that crack nucleation and propagation are the leading causes of unexplained instrument separation. If we can reduce crack initiation, we can reduce separation.

The EndoSequence file, in all sizes and tapers, has been subjected to the process of electropolishing. This is very significant because of the benefits gained from such a treatment.

Electropolishing removes many of the imperfections found in nickel titanium files that can have catastrophic consequences. For example, electropolishing is very effective at inhibiting the aforementioned crack propagation in nickel titanium blanks. These cracks have been shown repeatedly to be a major cause of instrument separation. Additionally, the creation of a superior finish will keep the edge of the instrument sharper, cleaner, and more durable. The result of these benefits is a rotary file with more cutting efficiency, less lateral resistance, and increased resistance to wear. Simply put, electropolishing makes any rotary file a safer and better rotary file (Fig. 3).

It also must be noted that, at the current time, the EndoSequence file is the only constant taper rotary file system that is subjected to an enhancement procedure, such as electropolishing. We truly believe this is a significant advance in the manufacturing of endodontic rotary files (Fig. 4).

The other endodontic rotary file that is electropolished is the European RaCe system. While this has had limited exposure in the United States, it does have a significant following in Europe. Furthermore, there is a recently completed study in Italy that deserves our attention.

Dr. Antonio Bonaccorso and others studied the fatigue resistance of rotary files in an attempt to assess whether metal treatment (electropolishing) had any effect on the accumulation of cyclic fatigue. As previously mentioned, cyclic fatigue is generated by canal curvatures and the methodology used in this study replicated clinical conditions found in curved canals. A total of 40 instruments were made to rotate freely on a sloped metal block at 300 RPM by a contra-angle mounted on an ATR Tecnika machine. The angle of curvature was calculated by Schneider’s method. In fact, the angle of curvature used was 40.5 degrees.

In this study, the instruments investigated were RaCe files (size 25/ .06 taper) and two groups were evaluated. Group A had 20 RaCe files that were electropolished while Group B was comprised of 20 RaCe files prior to being electropolished. Each instrument was operated until it separated. The separation time was noted for each instrument. The surface of each instrument was observed (before and after operation) with scanning electron microscopy.

The results were consistent and noteworthy. They consistently demonstrated that the time to instrument failure (as a result of accumulated cyclic fatigue) was significantly different. “The group A (electropolished) had the highest values in time of failure (time: 20 seconds). Group B (without surface treatment) was the lower value (time: 6 seconds) in time of failure.” Additionally, “microscopic evaluation indicated that the RaCe instruments with surface treatment (Group A) showed an absence of prominent manufacturing marks in comparison to the instruments without surface treatment (Group B).” This is a key finding, but why?

The absence of manufacturing marks or grooves on rotary files is important. As the authors point out, “Cracks associated with fatigue failure almost always initiate (or nucleate) on the surface of a component at some point of stress concentration. Crack nucleation sites include surface scratches, keyways, dents, and the like.”

The foremost issue in this investigation is summarized in the conclusion. “During machining operations, small scratches and grooves are invariably introduced into the workpiece surface by cutting tool action. These surface markings can limit the fatigue life. It has been observed that improving the surface finish by electropolishing will enhance fatigue life significantly.”

We have seen the evidence that electropolishing does make a difference in the reduction of cyclic fatigue and increased resistance to separation, but what can we expect to see in the future? Will we see more rotary files electropolished? Perhaps, but it is more likely that we will see companies utilize stainless steel and then attempt to coat the stainless steel files with one of the available industrial coatings. While this may circumvent certain patent considerations, it will most assuredly result in a stiffer file and one that will be considerably more expensive than those electropolished.

While there will always be some element of separation with all endodontic files, this can be kept to a minimum by the single use of rotary files and by using files that have undergone a surface enhancement procedure. Electropolishing, with its multiple advantages, is the ideal method for enhancing nickel titanium rotary files.

Dr. Dennis Brave is a diplomate of the American Board of Endodontics and a member of the College of Diplomates. In endodontic practice for 27 years, he was the senior managing partner of a group specialty practice. Dr. Brave, formerly an associate clinical professor at the University of Pennsylvania, currently holds a staff position at The Johns Hopkins Hospital. Dr. Kenneth Koch is the founder and past director of the program in postdoctoral endodontics at the Harvard School of Dental Medicine. In addition to having maintained a private practice limited to endodontics, he has written numerous articles on endodontics and has lectured worldwide. They can be reached at Real World Endo at (866) 793-3636 or through www.realworldendo.com.

The advantages of electropolishing as listed at www.amtbe.com/polishing.html

- Easy to treat complex shapes - curved, machined, drilled

- Easy process control; it guarantees process stability

- Easy automation; it offers high production capability

- Easy to treat a variety of surfaces - sand-blasted, oxidized, pickled, laser-cut, etched, etc.

- Precision leveling, down to 0.5 micron

- Very fast process depending on the shape and size

- Covers very large range of alloys - titanium, nitinol, cobalt

- Flexibility; different components on the same line

- Cost-effectiveness

- Surface roughness is monitored with Scanning Electron Microscopy