By Steven Rose, Orange County Cosmetic Dental Laboratory

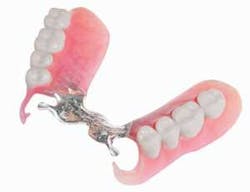

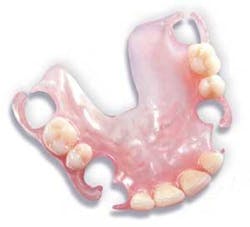

Elective cosmetic procedures have never been more popular. This demand has crossed over into the realm of removable partials as well. Patients are demanding excellent esthetics as well as exceptional functionality of their dentures because they can. Due to great strides in technology and application, they no longer have to deal with unsightly clasps, unnatural coloration, or uncomfortable fit (figure 1). One of the most popular dentures available today is the Valplast® flexible partial because of its esthetics, durability, and malleability (figure 2). Valplast is made of a durable thermoplastic nylon material and comes with a lifetime warranty against breakage from the manufacturer. Since it is monomer-free, Valplast is also ideal for patients who are allergic to acrylic monomer. Valplast can also be used in combination with a metal framework or precision attachments (figure 3). More importantly, the Valplast partial process is straightforward and fairly typical from start to finish, which makes the patients’ demands easier for the dental practitioner to satisfy.

null

null

null

Valplast preparation techniques

Prior to starting a Valplast partial, a cast model should be thoroughly examined. Valplast uses a tissue clasp technique for retention (figure 4). The correct level of flexibility of the thermoplastic resin allows designs to utilize tissue undercuts and portions of the abutment tooth for retention (figure 5). Clasp placement will depend on the individual case. For instance, a Kennedy Class IV arch for esthetics would want minimal coverage of the teeth, while with a posterior case, clasps should provide utmost support and stability.

null

An alginate impression of the arch with an opposing model poured immediately is recommended. AccuDent System is suggested because it practically eliminates the need for custom trays in 90 percent of cases, allowing you to create master casts in a more efficient manner. Teeth try-ins are recommended in anterior, free end saddle cases, or with particular patients. Valplast teeth try-ins are only in wax, as they are solely to view the setup of the teeth, not to display the retention of the partial. In most cases, dentists prefer to go straight to finish with a custom bite.

The role of the laboratory

The laboratory will design the case on the master model, making full use of tissue undercuts for retention. It is necessary for relief and blocking to be done in wax. All undercuts that affect the path of insertion will be blocked out. However, some undercuts, often on the buccal and distal, should not be blocked out because they will be utilized for retention. The laboratory will then duplicate the model and wax the case for completion on the duplicate model. After investing and washing out, the teeth will be prepared for mechanical retention of pontics. Valplast needs a thinner wax-up than conventional acrylic partials. There should not be any bulky flanges. The Valplast resin will next be injected into a closed flask. After the case is deflasked, it is then finished and fit on the master model. The Valplast will then be polished. The case should then go through disinfecting procedures and be delivered in water. Laboratories such as O.C. Cosmetic Dental Laboratory include a green stone bur for any necessary modifications and include a cleaner solution.

Insertion techniques for Valplast

After unpacking the case and examining the finished partial on the master model, make sure your case was properly blocked out by making sure there is no space between the clasp and tooth. Prior to insertion in the patient’s mouth, immerse the case in very hot tap water for about 60 seconds. Allow the partial to cool down to just the point where it will be tolerated by the patient. Gently insert the partial in the patient’s mouth. The hot water treatment permits a very smooth initial insertion and a good adaptation with the natural tissues in the mouth. If the patient senses any discomfort because of the tightness of a clasp, the clasp may be loosened slightly by immersing that area of the partial in hot water and bending the clasp outward. If a clasp requires tightening, the clasp area may be immersed in hot water and bent inward to tighten.

How to make adjustments

Making adjustments to Valplast can be made easy with the correct tools and information. Valplast is a thermoplastic and must be handled differently than acrylic. To make reductions, it is essential to use a fairly coarse grinding wheel or a parallel steel bur (vulcanite bur). The resin will melt if there is prolonged contact with a bur or wheel; therefore, it is essential to move the instrument over the surface continuously (figure 6). Minor relief can be made with a rubber wheel or a vulcanite bur. If there are any threads remaining, these can be removed with a sharp blade. Any roughness on the surface can be smoothed with a brown rubber wheel. The surface may be repolished after rubberizing (if needed) using coarse pumice, brown tripoli, and the Val-Shine polishing compound. The grinding tools, Valplast knife, and polishing agents can all be obtained directly from Valplast International Corp.

null

Valplast repairs and relines

Many dentists have the misconception that Valplast cannot be added to or relined. In fact, they are easy lab procedures, but cannot be done chairside. In order to add or replace a tooth to a Valplast partial, a pickup impression is necessary. The laboratory will utilize either a welding technique for small repairs or an injection technique for larger repairs and retentive additions. In order to do a reline on a Valplast, the laboratory will need a rubber base reline impression and a pickup impression over it. Valplast relines with individual saddles can normally be relined using the injection repair technique, but in the case where an overall reline is indicated, the case is jumped into a new base.

Summary

Valplast is an excellent material for partial dentures achieving superior strength and esthetics. Valplast has been around for more than 50 years with a great reputation for providing an alternative to metal partials. For more information, call O.C. Cosmetic Dental Laboratory at (800) 696-7265 or Valplast International at (800) 843-2861.

Steven Rose is a co-owner of O.C. Cosmetic Dental Laboratory. He began his laboratory career with renowned Posca Family over a decade ago. Specializing in removable prosthetics, he has helped with the design of several innovative partial designs such as the thermoplastic cast rest seat design and the Advantalock partial. Lately, O.C. Cosmetic has been at the helm of innovation in removable prosthodontics. Rose may be reached via email at [email protected].